Safe work method statement (SWMS) procedure

A safe work method statement (SWMS) is required for the high risk construction work activities (HRCW) defined in the WHS Regulations.

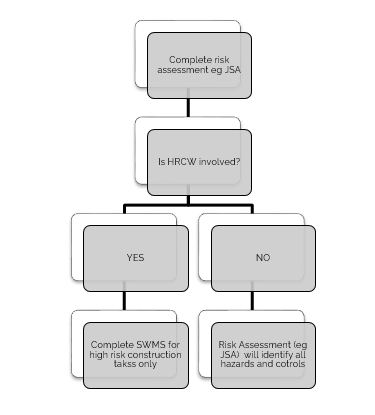

A risk assessment should be first conducted to determine any hazards associated with the work being performed.

Purpose

SWMS primary purpose is to help persons conducting a business or undertaking (PCBUs), supervisors and workers implement and monitor the control measures established at the workplace to ensure high risk construction work (HRCW) is carried out safely.

For other construction activities a SWMS is not required

This procedure relates to those involved in preparing a SWMS before commencing HRCW.

Overview

Any HRCW activities will be identified when you do an initial Risk Assessment A JSA is one form of risk assessment tool.

A SWMS is a written document that must identify

- the high risk construction work activities to be carried out at a workplace

- the hazards and risks to health and safety arising from these activities

- the measures to be implemented to control the risks and;

- how the control measures are to be implemented monitored and reviewed.

SWMS should be used as tool for consultation and should be prepared in consultation with all relevant persons. A SWMS should escribe to workers in clear terms how following control measures will manage those risks

High risk construction work

There are 18 activities that are classed as high risk construction work due to the significant potential for serious harm that is often associated with those activities.

The 18 HRCW activities are work that:

- involves a risk of a person falling more than 3 metres

- is carried out on a telecommunication tower

- involves demolition of an element of a structure that is load-bearing or otherwise related to the physical integrity of the structure

- involves, or is likely to involve, the disturbance of asbestos

- involves structural alterations or repairs that require temporary support to prevent collapse

- is carried out in or near a confined space

- is carried out in or near a shaft or trench with an excavated depth greater than 1.5 metres; or a tunnel

- involves the use of explosives

- is carried out on or near pressurised gas distribution mains or piping

- is carried out on or near chemical, fuel or refrigerant lines

- is carried out on or near energised electrical installations or services

- is carried out in an area that may have a contaminated or flammable atmosphere (this includes airborne contaminants (eg fumes, vapours, gases, mists and dusts)

- involves tilt-up or precast concrete

- is carried out on, in or adjacent to a road, railway, shipping lane or other traffic corridor that is in use by traffic other than pedestrians

- is carried out in an area at a workplace in which there is any movement of powered mobile plant

- is carried out in an area in which there are artificial extremes of temperature

- is carried out in or near water or other liquid that involves a risk of drowning

- involves diving work.

Procedure

Follow the procedure to develop a SWMS.

Prepare a SWMS

A high risk construction work SWMS is a document, prepared in consultation with all relevant persons, that accounts for the workplace-specific circumstances that may affect the way in which the high risk construction work is done.

Your SWMS needs to:

- identify the hazards and risks of HRCW

- describe to workers in clear terms how following control measures will manage those risks.

As a minimum, the SWMS must:

- identify the work that is HRCW

- state the hazards and risks to health and safety from that work

- clearly detail the measures selected to control those risks

- describe how the risk control measures will be implemented

- take into account the circumstances at the workplace that may affect the way in which the work is carried out

- include details of the WHS management plan at the workplace , if the work is carried out in connection with a construction project (A WHS management plan is required for construction projects For construction projects with a total value greater than $450,000).

- be set out and expressed in a way that is readily accessible and understandable to the workers who use it.

The SWMS should also identify the:

- date and location the HRCW is to be performed

- person/s responsible for ensuring selected risk controls are installed and maintained

- names of workers consulted in the document’s preparation.

While there are broader duties to control all workplace hazards and risks, only hazards and risks that are directly related to prescribed HRCW activities need be included in a SWMS.

Develop a SWMS

A typical approach to developing a SWMS is to:

- assemble the relevant workers, their HSRs and supervisors; ideally at the location of proposed works – there is a legal duty to consult affected workers and their HSRs when identifying hazards or measures to control risk

- review the proposed works and consider any site specific factors with potential to impact the works

- ensure all proposed HRCW activities are identified and the hazards and risks are listed

- select the risk control measures and describe them alongside each of the hazards and risks that are listed.

When selecting risk control measures for HRCW, first seek to eliminate that risk so far as is reasonably practicable (e.g. having overhead powerlines de-energised).

If a risk cannot be eliminated, it must be reduced so far as is reasonably practicable, by utilising the hierarchy of controls, and implementing one (or a combination) of the following:

- implementing any hazard-specific controls required by law

- substituting with a lower risk activity, procedure, plant, process or substance (e.g. using scaffold in preference to ladders)

- isolating persons from the hazard (e.g. fence off areas for mobile plant operation)

- using engineering controls (e.g. trench shields, guard rails, mechanical ventilation).

This process should be used to control any risks that are not covered by specific duties in other parts of the WHS Regulations. For how to control risks arising from hazards such as manual handling, noise, falls, confined spaces, plant and machinery, hazardous substances, asbestos and lead, see those sections of the WHS Regulations.

If after implementation of the above controls so far as is reasonably practicable, a risk to health or safety still remains, reduce that risk, so far as is reasonably practicable, by using administrative controls (e.g. safety training, work instructions, warning signs, supervision).

If after implementation of administrative controls so far as is reasonably practicable, a risk to health or safety still remains, reduce that risk, so far as is reasonably practicable, by providing personal protective equipment (PPE) (e.g. hearing protection, high visibility clothing, respiratory protection) or a combination of appropriate PPE.

It is not acceptable to use a generic SWMS unless it is altered to make it site-specific. This can be done by reviewing and revising it as necessary regarding its suitability for the specific environment and circumstances in which the HRCW will be performed.

Implement and review a SWMS

High risk construction work must be carried out in accordance with the SWMS.

If work is not being carried out in accordance with the SWMS then it must stop immediately or as soon as it is safe to do so. In these cases the SWMS should be reviewed and if necessary revised to reflect the safest way to carry out the work that is reasonably practicable. Work must not resume until the work can be carried out in accordance with the SWMS.

A PCBU must also ensure a SWMS is reviewed and revised if the measures put in place to control risks to health and safety are revised.

Record keeping

A copy of the SWMS must be retained for the duration of the HRCW.

The SWMS should be kept available at the location of the HRCW, where it can be readily referenced by affected persons, or reviewed and revised as necessary.

SWMS may be stored in an electronic format (e.g. on a smartphone) so the persons doing the work have ready access to the document for reference.

SWMS self-assessment tool

Use the SWMS self-assessment tool to ensure your Safe Work Method Statement for high risk construction work complies with the legislation. The list is similar to that used by SafeWork SA inspectors when they check SWMS compliance.

Speak with your manager/supervisor if you need access to this tool .

Roles and responsibilities

The duty to prepare a SWMS before commencing HRCW rests with the PCBU of the workers (or the self-employed person) undertaking the HRCW.

There will often be multiple PCBUs to whom that duty applies (e.g. the builder and sub-contractors). In such cases, the sub-contractor is normally best positioned to understand and control the hazards and risks associated with the types of HRCW they are engaged to perform.

A builder may agree to prepare the SWMS on behalf of or in conjunction with their sub-contractor, providing this is done in consultation with affected workers and their health and safety representatives (HSRs).

The WHS Regulations apply to each one of these PCBUs, as far as they control the work. Each PCBU must, so far as is reasonably practicable, manage the risks to the health and safety of workers, including contractors who are within the PCBUs control and anyone else affected by their work.

PCBU

PCBUs (including self-employed persons ) are responsible for;

- Preparing a safe work method statement (SWMS) before commencing high risk construction work (HRCW).

- Stopping the HRCW immediately or as soon as it is safe to do so, and not allow it to resume until the SWMS is complied with or reviewed and revised as necessary.

- Monitor work to ensure the SWMS is being complied with

- Duty holders (builders and sub-contractor) must ensure that once a SWMS has been developed and implemented, the HRCW to which it relates is performed in accordance with that SWMS.

Managers and supervisors

Managers and Supervisors are responsible for;

- Ensuring workers and HSRs are consulted in the preparation of SWMS

- Making sure SWMS can be understood by workers, including those from non-English speaking backgrounds

- Keeping SWMS available at the location of the HRCW, where it can be readily referenced by affected persons, or reviewed and revised as necessary

- Stopping work, if the work is not being carried out in accordance with the SWMS

Workers

Workers are responsible for:

- Performing work in accordance with SWMS

- Reporting If the work is not being carried out in accordance with the SWMS

Work Health & Safety Act 2012 (SA)

Work Health & Safety Regulations 2012 (SA)

Code of Practice: Construction work

Safe Work Australia – Safe work method statement for high risk construction work – information sheet

Risk management policy

Rick management procedure

Hazard

Something in, or that may be in, the work environment that has the potential to cause harm (injury, illness, or death) to a person.

Risk

The chance (or likelihood) that a hazard will cause harm to a person.

Control measure

A thing, work process or system of work that controls the hazard or risk.

HRCW

High risk construction work

HSR

Health and safety representatives

JSA

Job Safety Analysis

Version 1.0 – Last updated 1/8/2022