Handling and storing gas cylinders policy

Purpose

This policy:

- sets a standard for PEER Construction in terms of WHS risks.

- aligns with the standard set by the PEER Construction Policies and procedures manual and legislative requirements especially Work Health and Safety Act and Regulations 2012, Codes of Practice, Dangerous Substances Act 1979, Dangerous Substances Regulations 2002 and the Environment Protection Act 1993 (EPA).

Scope

This policy applies to all workers and others who store and handle gas cylinders at PEER Construction.

Types of gas cylinders

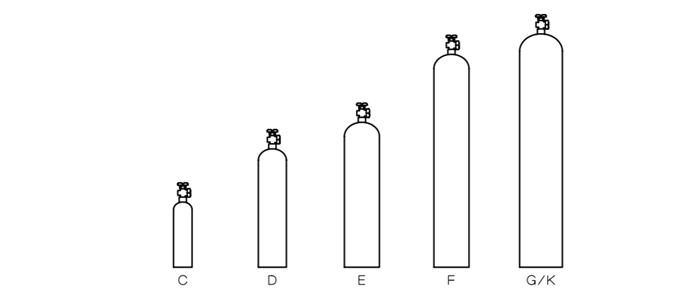

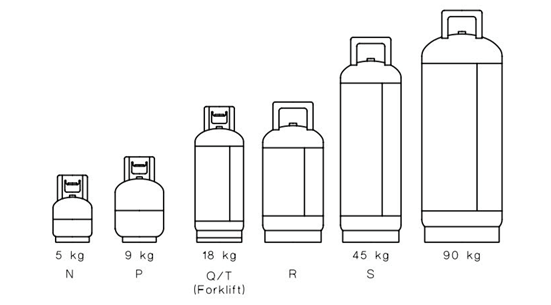

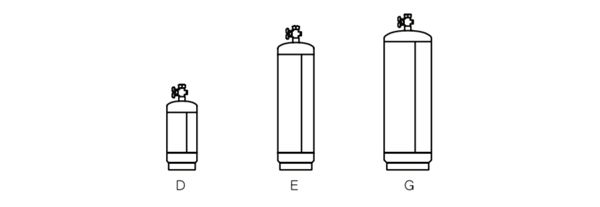

There are three types of gas cylinders usually available in a variety of sizes:

High pressure with gases that include nitrogen, helium, hydrogen, oxygen and carbon dioxide.

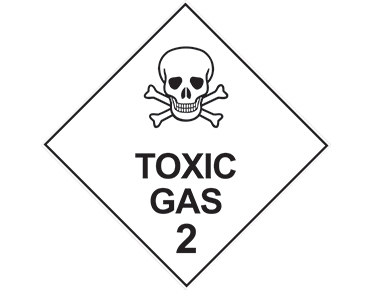

Classes of gases

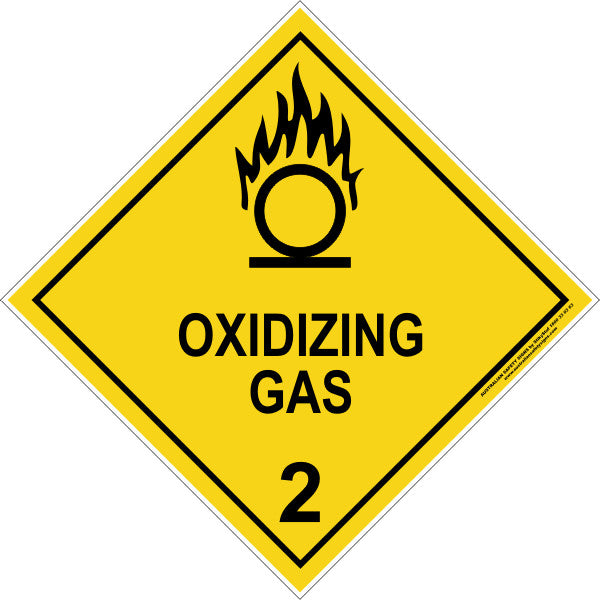

The following shows the four main classes of gases.

The class of gas defines its physical properties and transport requirements. need to be considered for storage and handling/usage requirements. Remember, some gases can also have corrosive properties, e.g. Ammonia.

Examples include: LPG, hydrogen, acetylene

Examples include: Compressed air, nitrogen, argon, carbon dioxide, helium

Examples include: Oxygen, nitrous oxide, Entonox (50% oxygen, 50% nitrous oxide)

Examples include: Methyl bromide, anhydrous ammonia, chlorine

Important information

The following is important information about handling and storing gas cylinders.

Identification and labelling

Gas cylinders are required to be labelled with:

- class label and any subsidiary risk labels

- the proper shipping name

- a four-digit United Nations number.

Manufacturer or importer’s name

Protect the markings on cylinders that identify the contents and mark the full/empty status on cylinders. Manufacturers paint gas cylinders using a colour coded system that is useful for identification. You should consult the manufacturer’s product catalogues for colour charts with this information.

NEVER alter markings, labelling or colour coding of gas cylinders supplied. They are a rented item and should be treated responsibly. The integrity and compliance of the gas cylinder is the supplier’s responsibility.

Cylinder valves

Cylinder valves open in an anticlockwise direction and close in a clockwise direction. Valves shall never be opened without a regulator attached. Always open cylinder valves slowly.

Regulators

Regulators come as single stage for short term applications and two stage for long term applications. Regulators are constructed from materials, such as brass or stainless steel.

The application will define the required regulator. If you are unsure of which kind of regulator to use, consult your gas supplier.

Regulators are designed to be fitted directly to the cylinder valve. No other fittings, connections or lubricants should be used to connect a regulator to a gas cylinder valve.

Regulators for flammable gases are left hand threaded and have a notch cut out of faces on the securing nut to distinguish them from non-flammable gas regulators.

WHS Considerations

Some WHS considerations are below.

Risks and hazards from gas cylinders

.Gas cylinders can be hazardous due to their physical size and weight and chemical characteristics. Hazards from gases are also subject to the chemical properties of each gas.

Hazards may be:

- Fire or explosion from the release of flammable gases near ignition sources.

- Spontaneous combustion from oxidising gases (e.g., oxygen or nitrous oxide).

- Exposure limits for all gases, especially toxic or corrosive gases.

- Asphyxiation from non-toxic, non-flammable gases by displacement of oxygen (e.g. nitrogen, carbon dioxide or argon)

- Incorrect storage.

- Faulty equipment or connections.

- Physical risks.

- Manual handling.

- Sudden release of gas if cylinder is damaged (torpedo effect).

- Pressure – compressed gas cylinders are filled to a pressure of 200-300 atmospheres.

- Gas density.

Safety data sheet (SDS)

Read, understand, and follow the markings on the cylinder, the label(s) on the cylinder, and the SDS to avoid misuse.

The SDS must be read to identify:

- chemical and physical hazards for each gas cylinder

- appropriate safe storage and handling practices

- the need for additional control measures

- first aid measures

- firefighting and emergency information

- density of the gas

- exposure limits

- flammability or explosiveness

- transport requirements.

Safe handling practices

- Securely install the valve protection devices, such as caps or guards, when the cylinder is not in use. EXEMPTION: G size cylinders will not have a protective cap or guard fitted.

- DO NOT roll or drag cylinders when moving them. Ensure that an appropriate mechanical handling device is used.

- Secure cylinders upright to a proper hand truck or cylinder cart with a restraining strap designed for the purpose. Cylinder size E and greater should be handled using mechanical assistance.

- Contact your gas supplier if more sophisticated handling of cylinders is required.

- DO NOT lift by the protective cap. If a cylinder does not have a handle, then use mechanical assistance to move it.

- DO NOT restrain cylinders around their necks or valve – restrain them around the main cylinder body at a height that will prevent them from falling over, that is 1/2 to 2/3 the height of the cylinder. Avoid dropping or knocking cylinders. Prevent damage to cylinders from impact from other objects (e.g. crashing into other cylinders). Some cylinders (e.g. acetylene) may react violently after being excessively shaken, heated, or knocked.

- Cylinders should NEVER be used as rollers to move other objects.

Personal Protective Equipment (PPE)

Recommended Personal Protective Equipment when using gas cylinders:

- Safety boots or enclosed footwear protect feet from being crushed by a cylinder falling or slipping.

- Leather gloves protect fingers from crush injuries and cuts from metal damage on cylinder and fingers and hands from sudden release of gas from cylinder valve. Note: gloves may hinder the handling of the cylinder due to a loss of dexterity. Choose suitable gloves.

- Safety glasses protect eyes from a sudden release of gas from cylinder valve and overpressure safety valves.

- Hearing protection protects ears from the noise of a sudden release of gas from cylinder valve or overpressure safety valves.

Using gas cylinders

- Always use gas cylinders in well ventilated areas. DO NOT use gas cylinders in confined spaces unless qualified to do so and the appropriate PPE is used.

- Know the gas you are using and possible reaction products. Additional mechanical ventilation may be required. Seek expert assistance in designing and installing mechanical ventilation systems.

- Ensure the correct regulator is used for the purpose.

- Ensure there is a suitable emergency response procedure in place.

- Wear appropriate PPE for the gas being used, refer to SDS.

- Ensure connections, fittings and lines are leak tight and suitable for use.

- Ensure that flammable and oxidising gases are not used near ignition sources.

- Disconnect empty cylinders from equipment to avoid backflow issues.

- Always close the cylinder valve when not in use.

- DO NOT use an empty cylinder as a waste receptacle.

- Fit non return valves in line if required.

- DO NOT use a gas cylinder that shows evidence of damage or corrosion. The gas cylinder is a rented item; its integrity is the responsibility of the gas supplier.

- If the cylinder contents cannot be clearly identified, DO NOT use it. Return it to the supplier.

Storing cylinders

- Always store gas cylinders upright and in a well-ventilated outdoor area. If stored incorrectly, cylinders may release liquid gas that can ignite and flare up uncontrollably, creating a major safety hazard.

- Make sure cylinders are protected from excess heat and potential ignition sources.

- When the cylinder is not connected to a gas appliance, put a sealing plug in the cylinder valve.

- Do not store cylinders in confined spaces.

- Different types of gas must be stored separately in accordance with regulations.

- The entry to stores must clearly show signage in accordance with Work Health and Safety Regulations 2012. This includes placarding and labelling.

Work Health and Safety Regulations 2012 (SA)

Codes of Practice, Dangerous Substances Act 1979

Dangerous Substances Regulations 2002

Environment Protection Act 1993

WHS policy

Version 1.0 – Last updated 6/2/2022